In the world of industrial manufacturing, custom rubber seals serve as unsung heroes, quietly ensuring the smooth operation of machinery across a myriad of sectors. Crafted by specialist manufacturers, these tailor-made components demonstrate the captivating intersection of precision engineering and material science, a topic that warrants a closer look. From the vast automotive industry to the intricacies of tiny electronic devices, the application of custom rubber seals is both vast and crucial. As we progress, we will explore the fascinating dynamics of this industry, the pivotal role these manufacturers play in several sectors, the rigorous process of manufacturing, and the challenges they encounter amidst the ever-evolving market demands. Stay tuned for an enriching journey into the world of custom rubber seal manufacturers.

Table of Contents

Key Takeaways

- Custom rubber seals play a crucial role in industrial manufacturing by ensuring smooth operation of machinery and improving product performance and durability.

- Custom auto glass rubber seals are important in the automotive industry as they provide airtight and secure closure between the vehicle body and windows, enhancing vehicle safety and comfort.

- Custom molded rubber seals are essential in various industries for airtight sealing and electrical insulation, with adaptability to diverse applications and the ability to withstand extreme conditions.

- Custom rubber window seals are designed to offer robust, leak-proof sealing solutions in the construction and automotive industries, improving energy efficiency and blocking drafts and noise.

Custom rubber seal manufacturers in Australia

In the realm of industrial manufacturing in Australia, a noteworthy sector includes custom rubber seal manufacturers, who meticulously design and produce an array of rubber seals tailored to meet the specific requirements of various industries such as automotive, construction, and other industrial applications. These manufacturers provide solutions that offer numerous benefits, such as improved product performance and enhanced durability, thereby playing a pivotal role in a multitude of industrial applications.

Choosing a manufacturer involves careful consideration of several factors, including their design capabilities, quality control processes, and experience in the industry. However, the design process is not without its challenges, with manufacturers often grappling with issues such as ensuring precise fit and optimal performance under varying operating conditions.

In the automotive industry, custom rubber seals are particularly crucial. They serve a myriad of applications, ranging from providing airtight sealing in engine components to reducing noise and vibration in the vehicle’s interior. Custom seals are essential for maintaining the overall performance and longevity of automotive parts.

Through the provision of tailored solutions, custom rubber seal manufacturers in Australia significantly contribute to enhancing the functionality and lifespan of products across several industries, thereby underlining the importance of their role in industrial manufacturing.

Custom auto glass rubber seals

Building on the significance of custom rubber seals in the automotive industry, a particular area of focus is the custom auto glass rubber seals. These are designed to provide an airtight and secure closure between the vehicle’s body and its windows.

Their usage provides several benefits:

- Improved vehicle safety: The seals prevent water, dust, and air from entering the vehicle, thereby reducing the risk of accidents.

- Enhanced comfort: They reduce noise and temperature variations, providing a comfortable ride.

When choosing these seals, consider the following factors: – Compatibility with the vehicle model – Durability and resistance against weather and chemical agents – Quality and performance of the seal

Despite their benefits, there can be common issues with these seals, such as leakage and wear and tear. Regular inspection and replacement are necessary to maintain their functionality.

The success of these seals lies in their innovative designs and materials. Manufacturers are using advanced materials like EPDM rubber, known for its superior weather resistance and durability. They are also using 3D technology for precise design and fit. These advancements ensure the seal’s effectiveness and longevity, further enhancing vehicle safety and comfort.

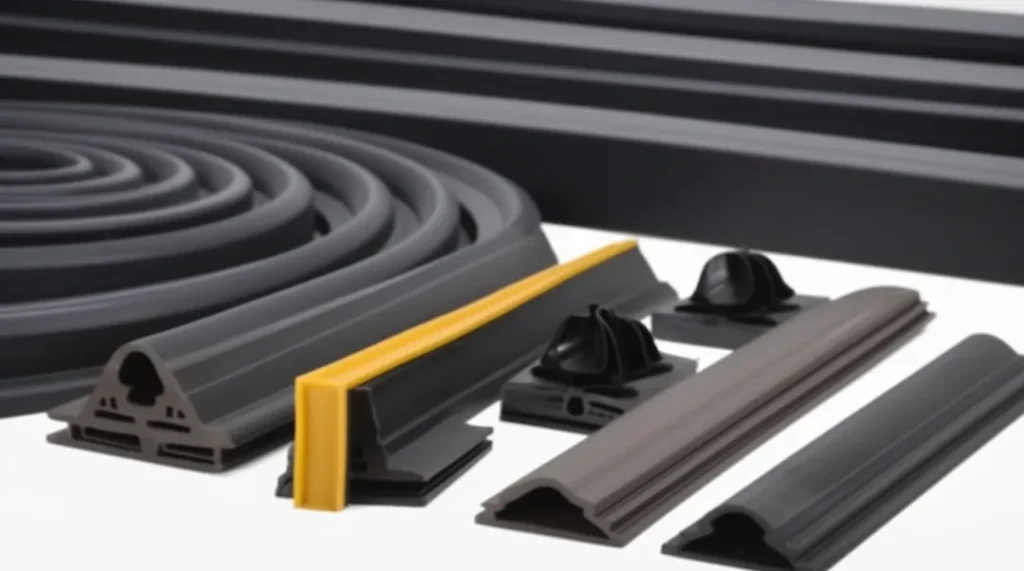

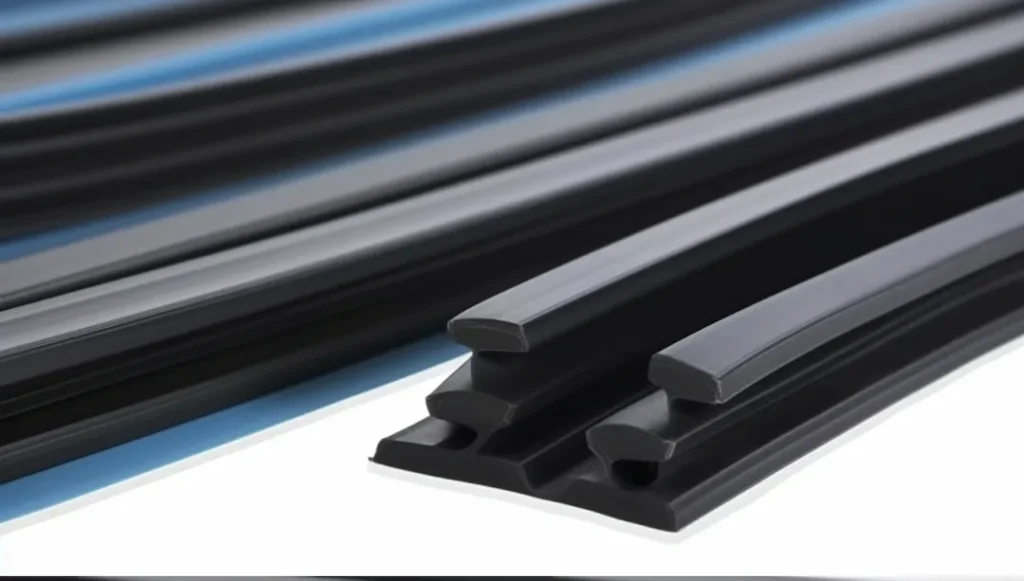

Custom molded rubber seal strip

Shifting our focus to custom-molded rubber seals, it’s important to note their crucial role in various industries, particularly in applications requiring airtight sealing and electrical insulation. The paramount advantages of custom-molded rubber seals encompass their adaptability to diverse applications, superior sealing capacity, and enhanced durability. They find extensive applications in industrial settings such as automotive, aerospace, and construction, where they provide efficient, leak-proof sealing solutions.

Choosing a custom rubber seal manufacturer demands careful consideration of factors such as their manufacturing capabilities, quality control measures, and expertise in specific industries. Ensuring the quality of custom-molded rubber seals involves rigorous testing procedures, including dimensional checks, hardness testing, and performance analysis under varying environmental conditions.

Designing custom rubber seals for specific applications poses challenges such as selecting appropriate materials that can withstand extreme temperatures, pressures, and corrosive substances while maintaining optimal sealing performance. Overcoming these challenges requires in-depth knowledge of material properties, advanced molding techniques, and precise design capabilities. Thus, partnering with a proficient custom rubber seal manufacturer becomes imperative for achieving superior quality and performance of custom-molded rubber seals.

Custom rubber window seals

Custom rubber window seals, often a critical component in construction and automotive industries, are specifically designed and manufactured to offer robust, leak-proof sealing solutions for a variety of window configurations. These seals are produced from a range of materials, including EPDM rubber, a substance noted for its exceptional weathering properties and resistance to UV light, ozone, and extreme temperatures.

Custom rubber window seals are available in a variety of forms:

Rubber gasket seals:

- Used to prevent the escape or ingress of fluids or gases

- Provides excellent resistance to wear and tear

EPDM rubber seals:

- Known for their weather resistance and durability

- Ideal for outdoor applications

Weatherstripping seals:

- Improve energy efficiency by preventing air leaks

- Enhance comfort by blocking drafts and noise

Industrial rubber seals:

- Designed for heavy-duty applications

- Offers high resistance to chemicals and extreme temperatures

Custom extruded seals:

- Created in complex shapes and profiles

- Provide superior sealing performance in unique applications

Custom sponge rubber seal

In the realm of specialized manufacturing, custom sponge rubber seals represent a unique blend of flexibility and resilience, often utilized in industries such as automotive, electronics, and HVAC for their superior sealing capabilities in a diverse array of applications. The custom sponge rubber material is a blend of synthetic rubber and cellular materials, known for its excellent compression set, thermal insulation, and noise reduction properties.

The benefits of custom sponge rubber seals are manifold. They are resistant to oil, ozone, and UV radiation, making them suitable for use in harsh environments. They also offer excellent shock absorption, thereby reducing wear and tear on machinery.

Design considerations for custom sponge rubber seals include the specific application, operating conditions, and environmental factors. The seal design must ensure optimal performance and longevity, hence the need for precision and expertise in the manufacturing process. The custom sponge rubber seal manufacturing process involves die cutting, extrusion, and molding, ensuring the seal’s conformity to precise measurements and specifications.

Customized dustproof rubber oil seal

Specialized in a variety of industrial applications, customized dust-proof rubber oil seals represent a critical component in machinery, providing effective protection against the ingress of dust, dirt, and other contaminants. These seals offer a range of benefits including improved machinery lifespan, reduced maintenance costs, and enhanced performance.

Key considerations when choosing a customized rubber oil seal include:

- The operating environment: Seals should withstand the specific conditions they will be exposed to, such as temperature changes and potential chemical interactions.

- The type of application: Different machinery and industrial applications require different types of seals. Common applications of dustproof rubber oil seals span across industries such as automotive, hydraulics, and pneumatics.

Proper installation is crucial to ensure the effectiveness of the seal. This includes ensuring the seal is the correct size, is not damaged during installation, and is correctly positioned.

Custom silicone rubber gasket seals

Building on the concept of bespoke sealing solutions, the realm of custom silicone rubber gasket seals opens up a myriad of applications, ranging from silicone rubber door and window seals to heat-resistant strips for ovens. The benefits of using custom silicone rubber seals are numerous; their resilience to extreme temperatures and ability to maintain structural integrity make them ideal for diverse industries such as automotive, construction, and food processing.

Choosing the right custom silicone rubber gasket seal for your application requires careful assessment of the operational environment, including temperature, pressure, and exposure to chemicals. Therefore, working with reputable manufacturers who prioritize quality control is vital to ensure the longevity and efficiency of the seal.

Custom silicone rubber seals offer flexibility in design, enabling a perfect fit for specific applications, a stark contrast to off the shelf options which may not perfectly match unique requirements. However, the latter may offer cost and time efficiency, being readily available. Quality control is essential in custom silicone rubber seal manufacturing to ensure the end product meets the rigorous standards of the various industries they serve.

Custom rubber door seals

Delving into the wide spectrum of bespoke sealing solutions, custom rubber door seals have carved a niche for themselves, specifically in applications involving car doors, garage doors, roller doors, shower doors, and automotive doors. The benefits of using custom rubber door seals are numerous, including enhanced durability, superior insulation, and improved aesthetics.

Considerations when choosing custom rubber door seals include: – Material quality – Manufacturing process – Cost-effectiveness

Problems with standard rubber door seals, such as poor fit, wear and tear, and inadequate insulation, can be resolved by opting for custom ones, designed to exact specifications.

The manufacturing process of custom rubber door seals involves careful design, molding, curing, and finishing, which ensure a high-quality, tailored product.

Installation and maintenance tips for custom rubber door seals include: – Ensuring proper fit during installation – Regular cleaning to avoid build-up of dirt and grime – Periodic replacement as necessary

Custom glass rubber seal

Often utilized in a multitude of applications such as large glass jars, aluminum window glasses, bathroom glasses, auto glasses, and glass panels, custom glass rubber seals are expertly designed and manufactured to meet precise specifications and needs.

The benefits of using custom rubber seals for glass installations include enhanced durability, improved sealing performance, and cost-effectiveness. However, common challenges faced when sourcing custom glass rubber seals involve finding the right manufacturer that can deliver high-quality seals that meet the exact requirements of the application.

The importance of choosing the right material for custom glass rubber seals cannot be overemphasized; it determines the seal’s performance, durability, and resistance to environmental factors. Therefore, material selection should be based on application requirements and environmental conditions.

To properly measure and specify custom rubber seals for glass applications, knowledge of the dimensions of the glass, the groove, and the seal’s desired compression rate is required.

Innovative designs and features available in custom glass rubber seals include pressure-sensitive adhesive backing, complex geometrical shapes, and co-extruded seals. These innovations offer increased functionality, ease of installation, and improved sealing performance, ensuring that the custom glass rubber seals provide optimal solutions for a wide range of applications.

Custom rubber seal from China

China is known for its vast manufacturing capabilities and expertise in producing a wide range of products, including custom rubber seals. Many businesses choose to source their custom rubber seals from China due to the cost-effectiveness and availability of high-quality products.

When looking for a custom rubber seal manufacturer in China, it is important to consider factors such as experience, production capacity, quality control measures, and certifications. Working with a reputable manufacturer with a proven track record in producing custom rubber seals is essential to ensure the delivery of high-quality products that meet your specific requirements.

Please feel free to contact us with any technical details for further information.