In recent years, China’s manufacturing sector has evolved significantly with advanced technology and customization becoming the backbone of its success. A key player in this transformative journey is Able Custom, a leading manufacturer of customized 7.5kw AC asynchronous motors. Their niche lies in creating a precise fusion of modern technology and customization to meet the distinct needs of their global clientele.

Table of Contents

Understanding AC Asynchronous Motors

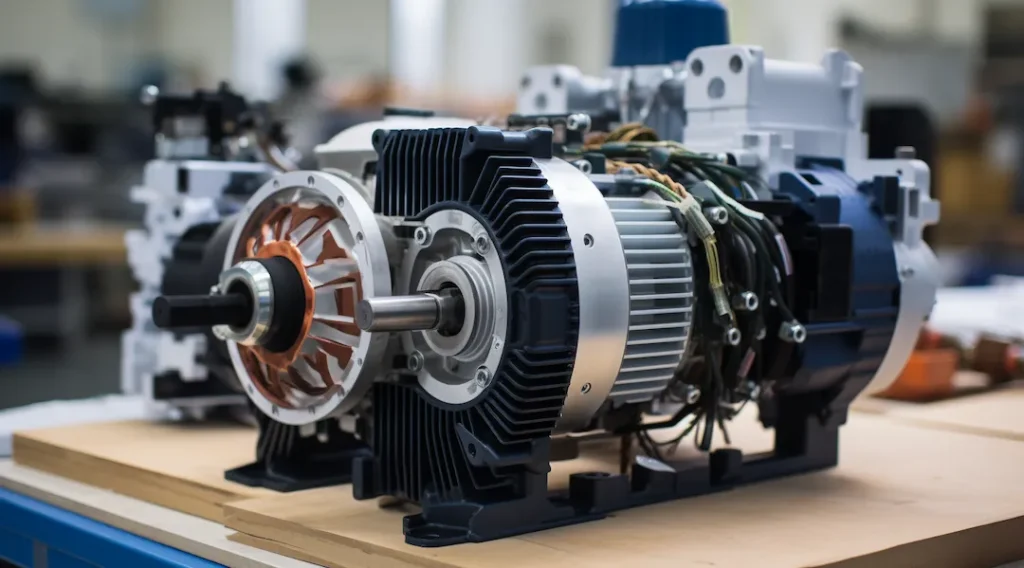

Diving into the technicalities, an AC Asynchronous Motor, often referred to as an induction motor, operates on the fundamental principle of electromagnetic induction. This type of motor utilizes alternating current, which is where it derives its name. It is crucial to understand that these motors do not operate at synchronous speed, hence the term ‘asynchronous’.

The Operational Mechanics of an AC Asynchronous Motor is quite sophisticated. It involves a complex interplay between the rotor, stator, and the alternating current supplied to the motor. The stator generates a rotating magnetic field, which induces a current in the rotor. This induced current then generates its own magnetic field that interacts with the initial field, causing the rotor to turn.

Motor Efficiency is another significant aspect of an AC Asynchronous Motor. The efficiency of these motors is influenced by several factors such as the quality of materials used, the accuracy of the assembly, and the design of the motor. The efficiency can be optimized by reducing losses in the motor, which include core losses, copper losses, and mechanical losses. A high-efficiency motor not only performs better but also conserves energy, making it more cost-effective and sustainable.

The Importance of Customization

While the intricacies and efficiency of AC asynchronous motors are undoubtedly essential, the customization of these units plays a pivotal role in meeting specific operational requirements and ensures optimal performance in diverse applications. Customization Benefits extend beyond mere flexibility, allowing for precise adjustments in torque, speed, and power factors to align with individual system demands.

The inherent design of AC asynchronous motors permits a broad range of modifications, from voltage and frequency alterations to structural changes. Tailored Solutions present an opportunity to enhance performance metrics and reduce energy consumption, thereby providing significant cost benefits. Custom motors can be designed to withstand extreme operating environments, ensuring longevity and operational efficiency.

The driving force behind customization is the unique operational characteristics of each application. By providing customized solutions, manufacturers can deliver motors that are finely tuned to the specific workload, operational conditions, and performance expectations of each client. This not only increases the lifespan and efficiency of the motors but also results in lower maintenance costs and improved overall system reliability. Therefore, customization is an indispensable aspect of AC Asynchronous Motor production that offers tangible benefits to all stakeholders.

Able Custom: Pioneers in Manufacturing

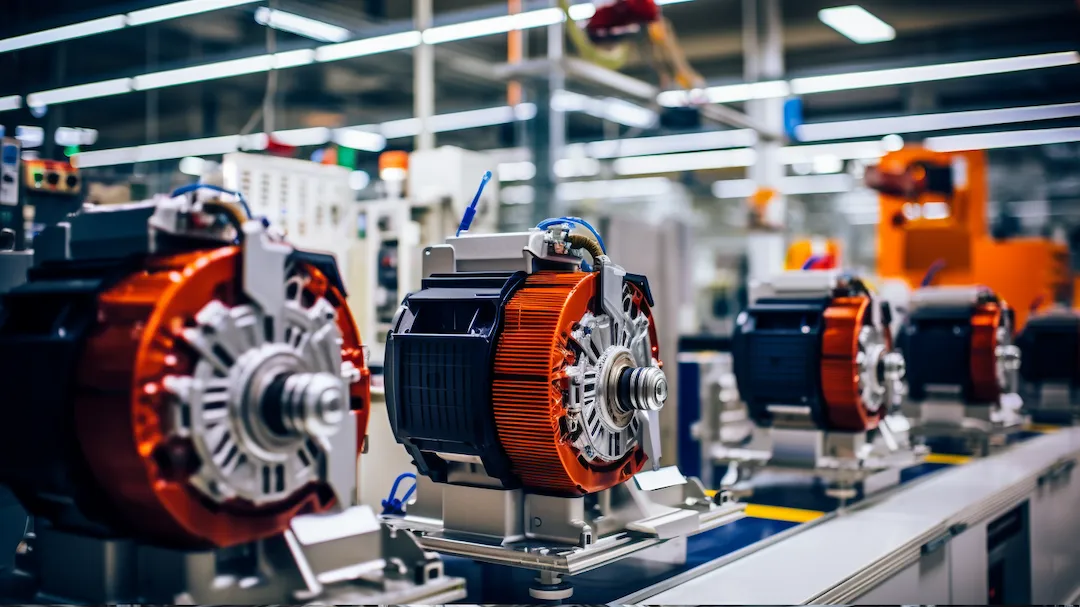

Among the leading manufacturers in the industry, Able Custom has established itself as a pioneer in the production of custom AC asynchronous motors, demonstrating exceptional technical expertise and a commitment to precision. Their manufacturing processes are a testament to their proficiency, exhibiting an elaborate sequence of design, assembly, and quality control stages.

Each process is meticulously managed and executed, ensuring that every motor produced meets the exact specifications required by the customers. Moreover, Able Custom has integrated a range of technological innovations into its operational practices. These include advanced CAD software for precise design creation, automated CNC machinery for accurate component fabrication, and sophisticated testing equipment for rigorous quality assessment.

Able Custom’s dedication to continuous improvement and innovation is evident in their pursuit of new manufacturing methodologies and techniques. They continually invest in research and development, striving to push the boundaries of what’s possible in the motor manufacturing sector. This relentless drive for innovation, coupled with their technical prowess and commitment to precision, sets Able Custom apart as a true pioneer in the manufacturing of customized 7.5kw AC Asynchronous Motors. Their achievements underscore the significant role they play in the broader landscape of China’s industrial manufacturing sector.

Unique Features of Able Custom Motors

Building on its innovative manufacturing techniques, Able Custom also distinguishes itself through its unique features engineered into each AC Asynchronous Motor.

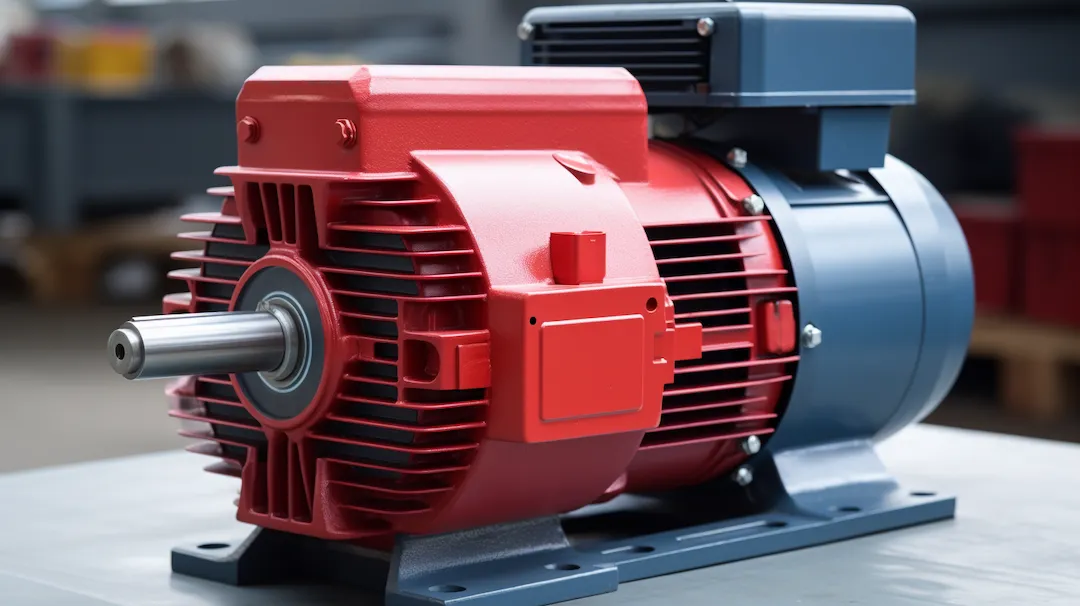

At the forefront of these unique features is Motor Durability. Able Custom motors are designed for longevity, using high-grade materials and precision engineering to withstand the rigors of sustained operation. The company’s motors are known for their robustness, with the ability to operate continuously under harsh conditions while maintaining optimal performance. This durability extends the lifespan of the motors, reducing the frequency and cost of replacements, and thereby contributing to the profitability and efficiency of operations for businesses.

Efficiency Enhancements also feature prominently in the design of Able custom ac motors. The company has adopted advanced motor winding techniques that optimize the flow of electric current, reducing energy losses and improving efficiency. Additionally, the motor’s cooling systems are designed to dissipate heat effectively, preventing overheating and allowing for sustained high-speed operation. These enhancements not only make Able Custom motors more energy efficient but also contribute to their overall performance and reliability.

Case Studies: Able Custom Success Stories

In examining the real-world applications of Able custom motors, several success stories emerge that showcase the superior performance, durability, and efficiency of these 7.5kw AC Asynchronous motors.

One notable case involves a leading manufacturer of heavy-duty industrial equipment. Faced with frequent motor failures and the associated downtime, they turned to Able Custom. The client testimonials reveal a dramatic improvement in equipment reliability post-integration of Able custom ac motors, resulting in increased operational efficiency and significant cost savings.

Another success story stems from a strategic partnership with a global provider of renewable energy solutions. They required a dependable motor for their wind turbine systems. Able Custom’s 7.5kw AC Asynchronous motor was selected after rigorous testing for its unrivaled performance under extreme environmental conditions. The partnership has resulted in an enhancement of the power generation capacity of the wind turbines and a boost in their overall productivity.

In both cases, Able Custom’s commitment to technical excellence, coupled with their ability to provide customized solutions, has resulted in successful real-world applications that underscore the impressive capabilities of these 7.5kw AC Asynchronous motors. These case studies clearly demonstrate the value that Able Custom brings to its strategic partnerships and the high level of client satisfaction they consistently achieve.

Conclusion

In conclusion, Able Custom’s ability to manufacture tailored 7.5kw AC asynchronous motors has revolutionized motor application in various industries. Their customization prowess, coupled with unique features, has positioned them as pioneers in the motor manufacturing sector. The success stories further validate the superior quality and performance of their motors. This innovation continues to drive efficiency, productivity, and sustainability, marking a significant step forward in the motor industry.